Insulated Metal Panels – PermaTherm

Insulated metal panels can be exterior or interior wall panels, composed of a metal skin laminated to the surface of an insulating foam core. Available in a variety of widths, insulated metal panels provide a solid thermal and moisture barrier for buildings and facilities in need of a contained, controlled environment. Buy insulated metal panels now!

Since 1987, PermaTherm has been manufacturing and producing insulated metal panels for virtually every insulated metal panel application in the market. Our insulated metal panels are most frequently utilized in lower temperature applications for food industry storage; however, those same IMPs have been successfully applied for a variety of unique construction projects across many different industries.

PermaTherm’s insulated metal panels provide a tightly controlled environment, eliminating the intrusion of outside air infiltration. Our IMPs offer unsurpassed thermal efficiency, providing the lowest cost-per-R-value on the market. PermaTherm panels provide architects, contractors, and building owners with unmatched energy-saving properties at budget-friendly prices.

Contact An Insulated Metal Panel Specialist Now

Only PermaTherm!

Since PermaTherm has officially announced the commissioning the newest state-of-the-art poly-iso line in North America, PermaTherm is now the only panel manufacturer who can deliver our EPS product line and a Foamed-In-Place Poly-Iso panel with the latest Gen-4 Closed cell technology. Much like PermaTherm’s EPS offering, the new PermaCore polyiso panel features:

- Gen 4 poly-iso insulate (no off-gassing)

- Maximum R-value per inch

- The highest EPA standards,

With PermaCore, you can choose between two panel-joint options:

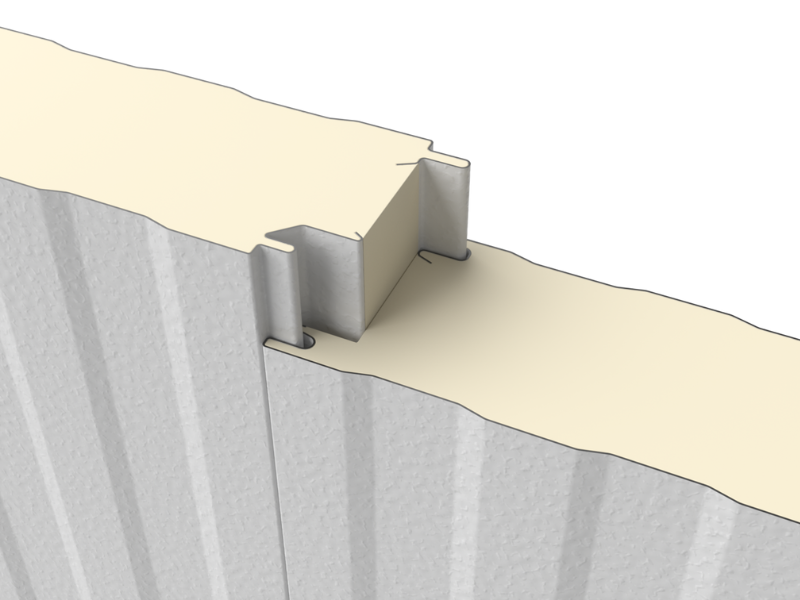

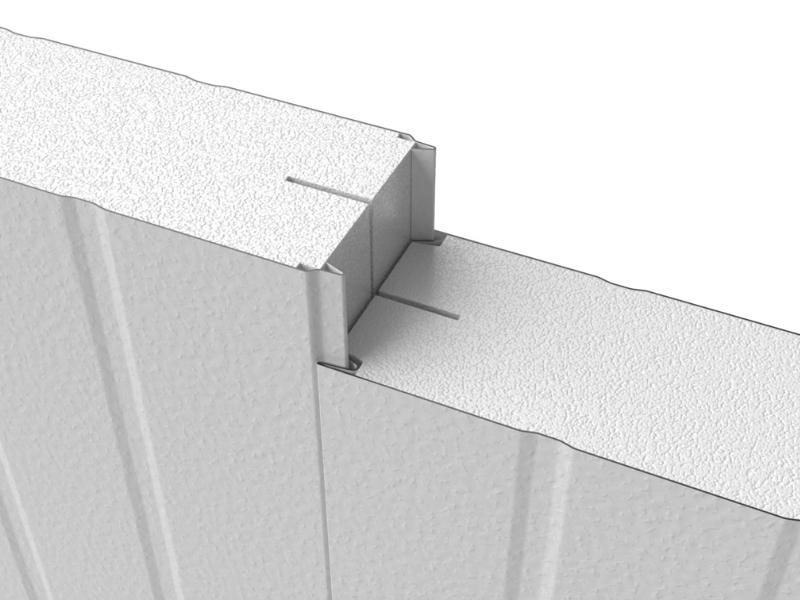

- PermaCore HF The hidden fastener joint for a variety of uses including exterior walls.

- PermaCore CS – The Cold storage joint, which virtually eliminates air entry/loss and thermal bridging. Available Profiles: Mesa | Light Mesa | Classic Shadow Line | Sleek (no Profile)

The PermaTherm Insulated Metal Panel Difference

Not only are our products exceptional – PermaTherm, as a company, is equally extraordinary.

We understand the importance of saving time and money with your next insulated panel project, and we will do everything we can to assure that occurs.

Our goal is to assist you along the way by offering the best practices for your future facility. Not many panel providers operate with such a hands-on approach regarding their customers, but we believe in seeing your construction through to the finish. insulated metal panels.

Our Hands-On Approach

We will consult by phone or in-person to make sure your job gets the attention you deserve. We can help with everything from the take-off of your project, to help with installers, contractors, flooring specialists, refrigeration experts and more. We are here to support you in every way throughout your construction project.

We will be glad to come by for a visit and share our immense experience, so you can feel confident that your project is moving in the right direction. By choosing PermaTherm insulated metal panels, you receive the benefit of our considerable knowledge at no additional charge.

Give us a call today and we will remove the complications, obstacles, and challenges for you so you can rest assured your project is a success.

Contact Our Specialists to Get An Estimate On Insulated Metal Panels