When insulating a cooler or freezer, there are certain requirements that must be met to keep your product safe and your environment up to snuff with the Department of Energy’s standards. The R-value of the panels used for your walk-in cooler or freezer is under particular scrutiny, as this must be correct, exact, and clearly labeled. In this article, we will discuss two primary factors that dictate the insulated metal panel R-value:

- The Material of the Panel

- The Thickness of the Panel

The Difference Between Poly-Iso and EPS Panels

When comparing the materials used in our insulated metal panels, Poly-Iso and EPS, the primary difference can be found in the R-value provided per inch of panel. EPS has a typical R-value rate of 4.4 per inch, while Poly-Iso has an average R-value of 8.0 per inch of thickness.

Naturally, as these two cores are measured on a per-inch basis, the second factor that impacts the R-value of an insulated panel would be its thickness.

Panel Thickness and R-value

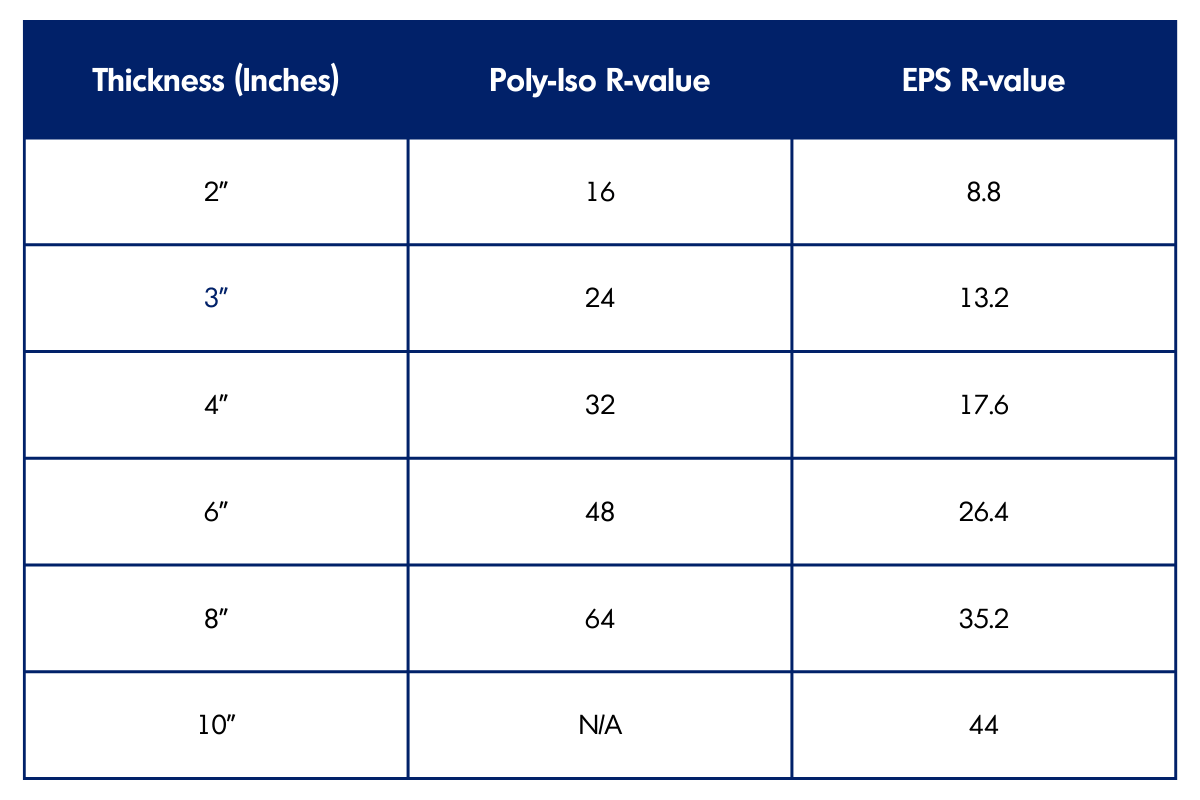

In the second half of our equation, panel thickness will exponentially change the R-value of the insulation solution you are implementing. Quite simply put, if a Poly-Iso panel is two inches thick with an average R-value of 8, the resulting R-value is 16. Thanks, algebra.

What does this equation look like at PermaTherm? Let’s look at the chart below.

What R-Value Do I Need for my Walk-In Cooler or Freezer?

Technically, the larger the space you are insulating, the lower the requirement for your R-value is. However, as you will want to ensure your product is safe and your environment is well-insulated (just like we do), we follow these rules of thumb.

If a cooler or freezer is kept at 28 degrees Fahrenheit or higher, we aim for an R-value of 24 or above. If you’re tempted to reference the chart above, we’ve got you. This would be a minimum of a 6-inch panel for EPS, or 3-inch for Poly-Iso (although there rarely is a need to go above 4-inch panels).

If a cooler or freezer is kept below 28 degrees Fahrenheit, we aim for a minimum R-value of 35. This would be a minimum of an 8-inch panel for EPS, or 5-inch for Poly-Iso. Why would someone go higher than those minimums? This can be for structural purposes, or even a state, local, or industry requirement that is more stringent than the DOE.

Get the Right Insulated Metal Panel R-value for Your Project

To ensure that your project has the right panels for the job, we encourage you to reach out to our team. Our onsite consultants are more than happy to take a look at your live project, and our solutions specialists are ready to assist during drawing reviews. Contact us, today.

Recent Comments