When it comes to setting up a new walk-in freezer or cooler, there is more to the installation process than meets the eye. In addition to studying product storage and processes, business owners must also consider temperature variables that affect the quality of their products and performance of the facility.

No owner is more familiar with this concept than our customer, Lloyd, the owner of a large grocery store and distribution company, reached out to PermaTherm, Inc. for a consultation before starting his newest walk-in freezer. An area of particular concern was reducing ice buildup within the freezer.

As Lloyd’s company grew, his existing facility was expanded and modified. Several of these expansions created miniscule breaches in the insulation system, causing ice accumulation over time. These alterations required a holistic analysis of the cold storage units to eliminate areas that had produced problems, like inventory and structural damage.

A Strategic System for Strategic Savings

After a thorough discovery period, PermaTherm presented an comprehensive insulation system strategy. PermaTherm’s plan included:

- Impermeable panel systems

- Airtight trim and accessories

- Temperature management guidelines and practices

- Guidance through the duration of the project

- Connections to a network of certified panel installers

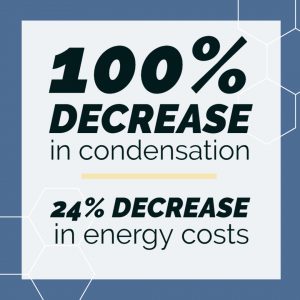

Within a week of completing and installing the new PermaTherm panels for his freezer, Bradley’s Foods noticed a 100% reduction of ice buildup compared to the previously built freezer.

By eliminating internal ice buildup, Lloyd’s company experienced a 27% decrease in inventory loss. Additionally, the company experienced decreased production interruptions and increased operation time. Over time they noticed a 24% decrease in energy expenditure, resulting in an increase in profit.

Continued Growth, Continued Profitability

In addition to the consultation services PermaTherm offered during initial construction, PermaTherm continued to check in with Lloyd yearly. The ongoing relationship gave Lloyd the confidence to continue setting up food storage and distribution locations around the south east. In the two years following their first consultation, Lloyd and PermaTherm collaborated on 3 walk-in coolers and 2 new freezers.

Lloyd explained that by working with a manufacturer with practical experience, his project was better positioned for a rapid payback. As a result, not only was Lloyd able to decrease his overall project cost upfront, but he also saw a continued increase in ROI in following years. With 27% decrease in inventory loss and 24% decrease in energy expenditure, Lloyd tracked returns year over year.

Lloyd explained that by working with a manufacturer with practical experience, his project was better positioned for a rapid payback. As a result, not only was Lloyd able to decrease his overall project cost upfront, but he also saw a continued increase in ROI in following years. With 27% decrease in inventory loss and 24% decrease in energy expenditure, Lloyd tracked returns year over year.

Lloyd recommended that businesses looking to install a cold storage facility speak with a consultant before beginning the planning process. By including a cold storage construction expert, holistic strategies with plans for long-term ROI are integrated at the outset of the project.

Recent Comments